Learn about House Demolition

Introduction and Outline: Why House Demolition Matters

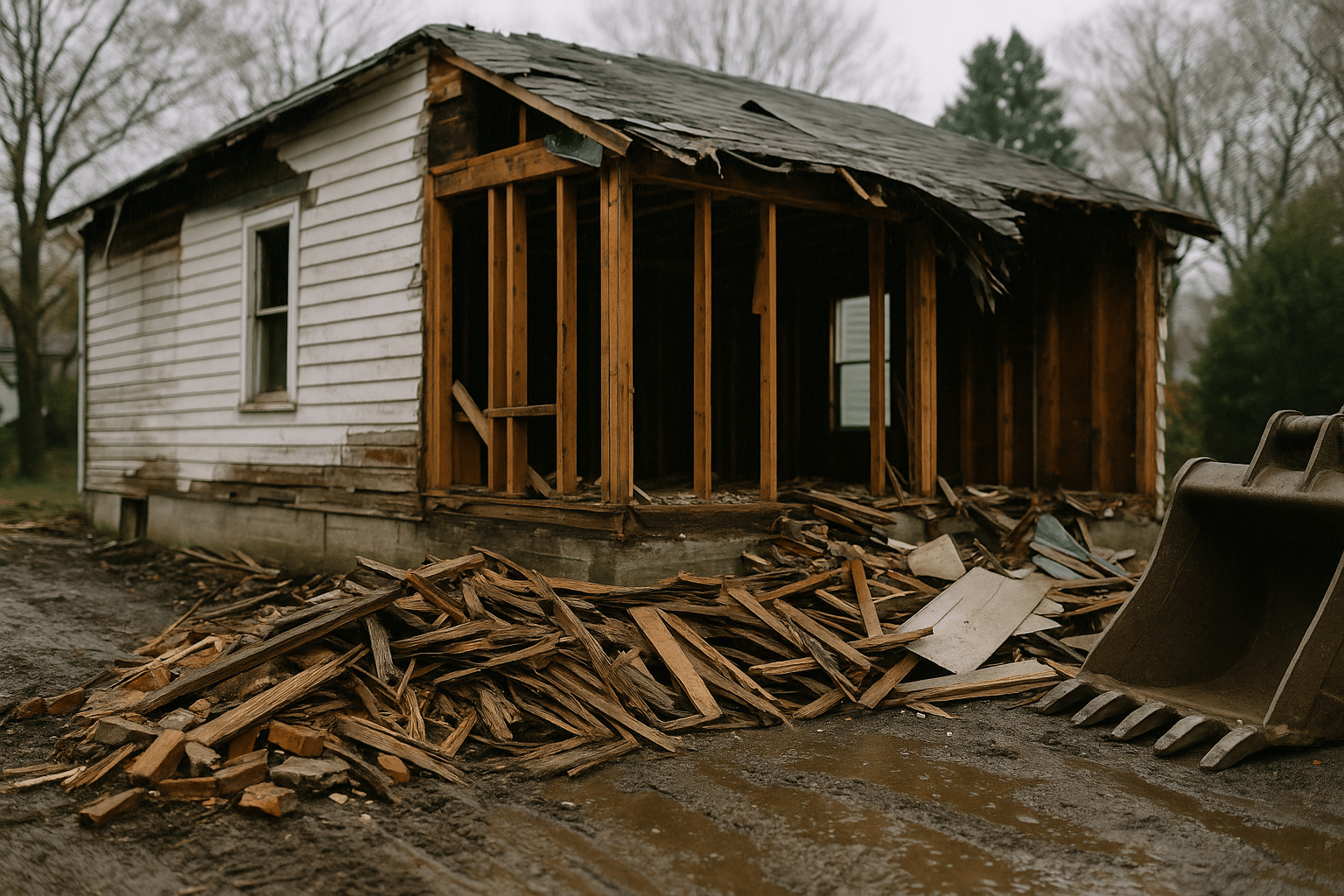

House demolition is more than a dramatic few hours with heavy equipment; it is a carefully staged process that protects people, safeguards neighboring property, meets legal obligations, and readies the site for smarter use. Whether you plan to rebuild, expand green space, or sell a cleared parcel, a well-run demolition can shorten your next project’s timeline and keep costs predictable. Conversely, skipping fundamentals—like verifying permits or disconnecting utilities—can trigger delays, fines, and unnecessary hazards. Before anything falls, you need a roadmap.

Outline of this guide:

– Planning, permits, and feasibility

– Methods and machinery: mechanical, selective, or deconstruction

– Safety, utilities, and hazardous materials

– Waste, recycling, and environmental impact

– Conclusion: budget, timeline, hiring, and next steps

Start with feasibility. A pre-demolition inspection identifies structural weaknesses, confirms property lines, and inventories materials that might be reusable or hazardous. If the house has historical features or is located in a conservation zone, additional approvals may be required. Many building departments ask for site plans, erosion-control measures, and proof of utility shutoffs before issuing a permit. Some communities also require neighbor notification or a visible posting period to give residents time to comment. These steps can add one to several weeks to your schedule, so align your expectations early.

Permitting usually covers the demolition activity itself, traffic control for trucks, and environmental safeguards such as dust suppression and stormwater protection. Insurers and lenders may request documentation of liability coverage, bonds, or letters confirming the contractor’s license is active. A clear scope of work prevents misunderstandings: Will the contractor remove the foundation? Who handles tree protection, septic decommissioning, or well abandonment? When the scope is specific, price comparisons become meaningful, and change orders remain the exception instead of the rule. Think of this planning phase as laying the runway—everything that follows lands more smoothly because you did the homework.

Methods and Machinery: Mechanical, Selective, or Deconstruction?

Demolition methods vary in speed, precision, and material recovery. For most single-family houses, mechanical demolition with an excavator is the workhorse. It relies on attachments—buckets, grapples, shears, and pulverizers—to peel away roofing and siding, sort debris, and load trucks efficiently. When access is tight, smaller loaders or compact excavators reduce the footprint and limit disturbance to neighboring structures. Water misters curb airborne dust, and mats or plywood protect driveways and tree roots during equipment movement.

Selective demolition targets specific rooms or systems—perhaps to retain a sound foundation, preserve a fireplace, or remove a damaged addition while saving the main structure. It takes more time but generates cleaner material streams that are easier to recycle and often reduces overall waste. Full deconstruction, the most labor-intensive approach, disassembles the building piece by piece to salvage lumber, fixtures, doors, and specialty items. It can divert a large share of materials from landfills, appealing to projects that prioritize reuse or must meet diversion requirements.

How to compare the options:

– Mechanical: Among the fastest and most cost-efficient; typical single-home timelines range from one to five days once utilities are clear.

– Selective: Slower but precise; useful where you need to protect portions of the structure or meet strict neighborhood constraints.

– Deconstruction: Highest material recovery; realistic for projects motivated by sustainability goals, tax-deductible donations of salvaged items where applicable, or unique materials.

Costs vary widely by region, access, and the presence of hazards. Industry sources commonly report indicative ranges such as mechanical removal at roughly $6–$18 per square foot, selective demolition at around $12–$30, and full deconstruction at about $20–$40. These figures are not quotes; they simply highlight how labor and logistics shift the math. Time frames scale similarly: deconstruction may take two to four weeks, while selective demolition often lands between one and two weeks. For many homeowners, the final choice blends budget discipline with practical outcomes—how quickly you need the site turned over, how much you value salvage, and whether site constraints narrow the field.

Safety First: Utilities, Site Controls, and Hazardous Materials

Safety starts before anyone touches the structure. Electricity, gas, water, sewer, and telecommunications must be disconnected and verified in writing. Overhead lines may need temporary relocation; underground services require a locate request to mark utilities and avoid strikes. Gas lines should be capped and pressure-tested by qualified personnel. Water and sewer disconnections are often inspected by the municipality to ensure caps are secure and backflow is prevented. These steps are not formality; they are your first firewall against fires, flooding, or electrocution.

Establishing site controls reduces risk to workers, pedestrians, and neighbors. Common measures include secure fencing, clear signage at access points, stabilized construction entrances to prevent mud tracking, and dust suppression through misting. Equipment zones and pedestrian paths should be marked, with an exclusion radius matching the structure’s height. Crews use personal protective equipment appropriate to conditions—hard hats, gloves, high-visibility vests, respiratory protection for dusty tasks, and hearing protection around machinery. A daily briefing helps the team adapt to changing conditions as the building’s integrity declines during takedown.

Older homes can harbor hazardous materials. Typical concerns include:

– Asbestos in floor tiles, pipe insulation, roofing, or textured coatings

– Lead in paint on trim, windows, and siding

– Mercury in thermostats and fluorescent lamps

– PCBs in certain mastics or older electrical components

– Refrigerants in appliances and HVAC systems

When surveys identify asbestos or other regulated materials, specialized abatement is required before demolition proceeds. This work is performed by licensed crews who contain the area, remove materials following strict procedures, and dispose of them at approved facilities. Lead-safe practices limit dust and protect workers and neighbors alike. Appliances and equipment containing refrigerants should be recovered by certified technicians to prevent illegal releases. Even simple details matter: nails protruding from boards, tensioned garage door springs, or compromised chimneys can cause injuries if not managed deliberately. Treat safety as an active system—layers of checks, not a single rule—and your project remains predictable rather than dramatic.

After the Fall: Waste, Recycling, and Environmental Impact

Once walls are down, the real orchestration begins: sorting, hauling, and documenting what leaves the site. Residential demolition typically yields mixed debris—wood framing, roofing, drywall, concrete, brick, metals, glass, and soils. The more you separate on-site, the easier it is to recycle economically. Clean concrete can be crushed for base material; metals move to scrap yards; unpainted lumber and heavy timbers may be reclaimed; fixtures find second lives in reuse centers. Roofing, drywall, and painted materials often head to facilities that can process or dispose of them according to local rules.

Many jurisdictions encourage, or even require, diversion targets. It is common to see goals ranging from 50–75% by weight for construction and demolition debris, with documentation through weight tickets and facility receipts. Deconstruction and selective approaches typically outperform mechanical demolition on diversion because materials remain intact and separable. Still, even mechanical jobs can hit strong numbers with a simple plan: a designated concrete pile, a metals bin, and a dedicated area for reusable items.

Environmental stewardship reaches beyond recycling. Dust control protects air quality; stabilized entrances and silt controls keep sediment out of storm drains; tree protection zones prevent root compaction from heavy equipment. Soil management matters, too: stripping and stockpiling topsoil preserves fertility for future landscaping, while compacted subgrade may need to be loosened before rebuilding. Some owners explore embodied carbon considerations—retaining a sound foundation or salvaging old-growth lumber can reduce the footprint of the next build. None of these steps require heroics; they reward a bit of forethought with cleaner outcomes and often modest savings on hauling and tipping fees.

Plan disposal logistics early:

– Confirm facility hours, material acceptance rules, and any contamination thresholds

– Schedule enough containers to avoid downtime or illegal stockpiles

– Keep records for permits, rebates, or green-building documentation

– Photograph salvage items before donation to support valuation where applicable

A tidy closeout not only looks professional; it also positions your site to pass final inspections, attract lenders’ confidence, and transition smoothly into design and construction for whatever comes next.

Conclusion: Budget, Timeline, Hiring, and Next Steps

Budget and schedule are where planning turns into action. For a typical single-family home, indicative costs often include permit and inspection fees, utility disconnects, abatement when needed, the demolition itself, hauling, and site restoration. While every market differs, many owners see total project figures that range widely based on size, access, and hazards. As a planning exercise, build a line-item estimate and include a 10–20% contingency to absorb surprises like hidden cisterns, extra concrete, or unforeseen abatement volumes. Transparent assumptions make later decisions easier to defend.

A practical schedule might look like this:

– Permits and historical or environmental clearances: 2–6 weeks

– Utility disconnects and locates: 1–3 weeks (often overlapping permits)

– Abatement: several days to 2+ weeks, depending on scope

– Demolition and debris removal: 1–7 days for most houses

– Final grading, erosion controls, and inspections: 2–7 days

Hiring the right team keeps that schedule real. Ask for copies of licenses and insurance, including general liability and workers’ compensation. Request a detailed scope that spells out inclusions and exclusions—foundation removal, backfill, compaction, tree protection, import or export of soils, erosion-control maintenance, and final grading tolerance. Look for a clear change-order process and a payment schedule tied to milestones such as utility verification, completion of abatement, demolition finish, and site restoration. References from recent, similar projects are more useful than distant highlights; you want proof they can operate cleanly in your neighborhood with your city’s rules.

As you approach the finish line, confirm closeout details: debris receipts, photos of underground disconnects, and any required erosion-control inspections. Consider how the cleared site will sit for the next phase—temporary seeding, gravel surfacing, or protective fencing can prevent erosion and unauthorized access. Finally, keep communication friendly with neighbors; a simple schedule notice and a quick thank you after cleanup go a long way toward goodwill.

In short, successful house demolition blends foresight, documented safety, and disciplined execution. Choose a method that matches your goals, manage hazards with respect, and treat waste as a resource rather than an afterthought. With a grounded budget, a realistic timeline, and a well-vetted contractor, you transform a teardown into a confident first step toward what’s next on your property.