Learn about Generator Installation

Outline:

– Assessing Power Needs and Choosing the Right Generator Type

– Site Selection, Permits, and Safety Essentials

– Transfer Switches and Electrical Integration

– Step-by-Step Installation Process and Commissioning

– Costs, Maintenance, and Long-Term Reliability

A well-installed generator turns a blackout from a scramble into a shrug. Weather extremes, infrastructure strain, and remote living all make a compelling case for dependable backup power. This guide focuses on practical, code-aware decisions that deliver safe operation without overcomplicating your project. Whether you’re powering a few essentials or planning whole-home coverage, the following sections unpack the why and how behind each step.

Assessing Power Needs and Choosing the Right Generator Type

Your installation starts with math, not metal. The goal is to match supply to demand with enough headroom for starting surges and future changes. Begin by listing every circuit or appliance you want to run during an outage, then separate continuous loads (what runs steadily) from intermittent or motor loads (what spikes on start). In typical homes, refrigerators run around 100–800 watts and can spike near 1,200–1,500 watts at startup; gas furnace blowers are often 400–700 watts; a 1/2 hp sump pump can draw 800–1,000 watts running and 1,500–2,000 watts at startup; a well pump can exceed 2,000 starting watts. Lighting with LEDs is wonderfully efficient—often 50–200 watts total for a few rooms. Office gear like routers and laptops sip power, typically under 100 watts combined. Add these, then apply a safety margin (often 20–30%) to accommodate inrush current and unexpected loads.

With a ballpark wattage in hand, choose a generator type that fits your scenario. Portable open-frame units are affordable and rugged for short-term outages; inverter portables provide cleaner power with quieter operation, helpful for sensitive electronics; permanently installed standby units connect to your electrical system and start automatically when utility power drops. Fuel choice shapes reliability and maintenance: gasoline is widely available but degrades in storage without stabilizer; diesel offers strong torque and efficiency with disciplined fuel care; propane stores well for years and burns cleanly; natural gas provides continuous fuel if the utility remains online. For many households focused on essentials—refrigeration, heat blower, lighting, and communications—3–6 kW can suffice with careful load management. Whole-home coverage often extends into the teens or low twenties in kilowatts, especially if air conditioning or deep-well pumps are included. If your property has three-phase service or commercial loads, consult an electrician to address phase balance and motor starting strategies.

Think of your load plan like packing a boat: every item matters, and weight distribution counts. Resist the urge to oversize dramatically—larger engines consume more fuel at light load and can “wet stack” on diesel, while undersizing leads to nuisance trips and voltage sag. A right-sized generator, aligned with a clear list of priority circuits, keeps essentials humming without waste.

Site Selection, Permits, and Safety Essentials

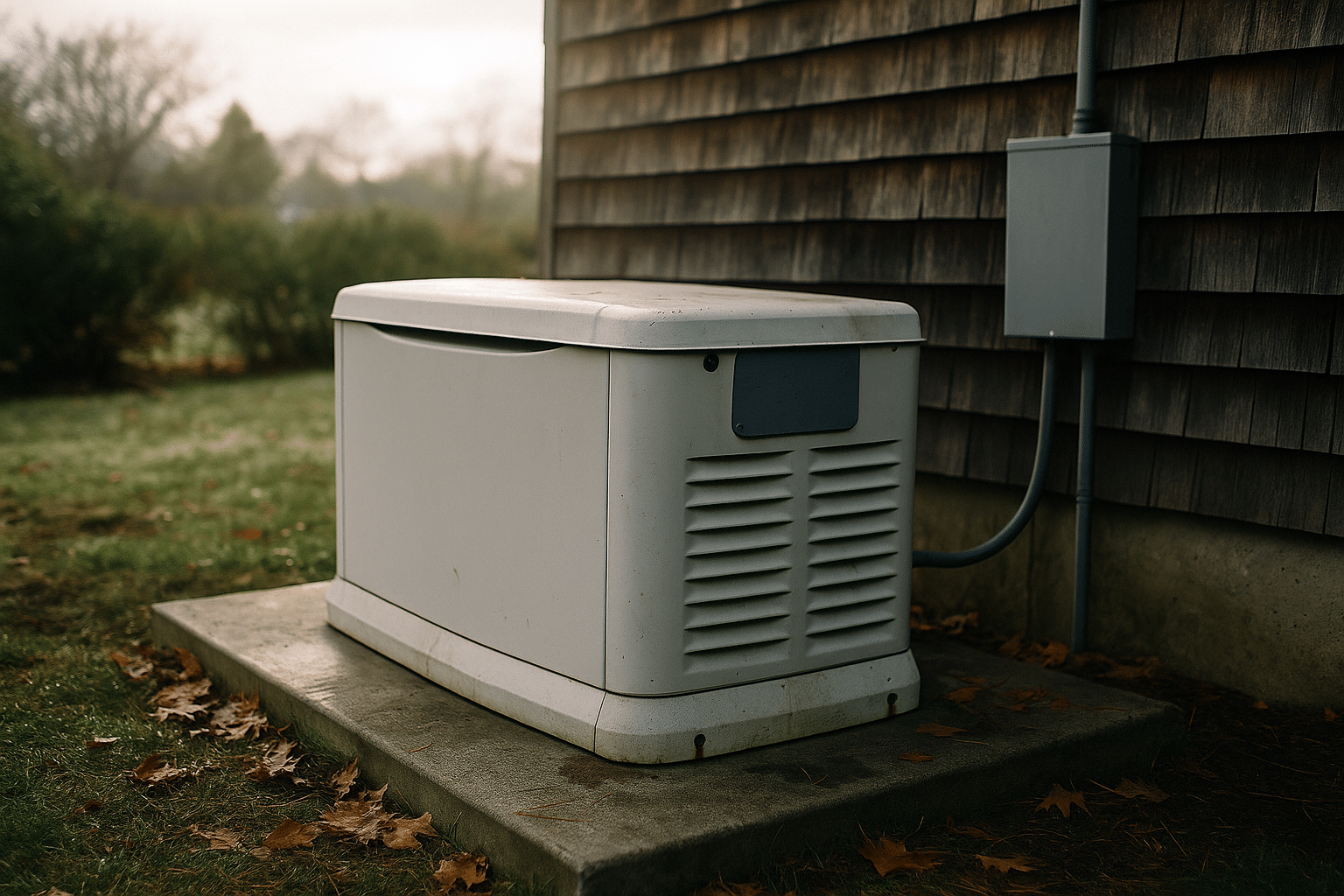

A generator’s location is as important as its horsepower. For permanently installed units, pick an outdoor spot with generous airflow and minimal flood risk. Maintain clearances per manufacturer instructions and local code; a common rule of thumb is to keep the unit at least several feet from openings like windows and doors to prevent exhaust infiltration. Place it on a level, non-combustible pad—concrete or compacted gravel—to reduce vibration and keep the housing clear of snow, leaves, and standing water. Avoid tight alcoves where exhaust can accumulate, and be considerate of sound: every 10 dB roughly doubles perceived loudness, so positioning behind landscaping, walls, or far-side elevations can help neighbors and your own sleep.

Permits and inspections aren’t red tape; they’re a safety net. Most jurisdictions require an electrical permit for the transfer equipment and a fuel permit for gas piping or tank connections. Local codes are typically based on national standards (for example, electrical and fuel gas codes) and may add stricter regional rules. Expect an inspection of conductor sizing, grounding and bonding, working clearances, transfer switch type, and the fuel system’s pressure/leak tests. Utilities may require notification when installing an automatic transfer switch to protect line crews. If your property has zoning restrictions or a homeowners’ association, check setback, screening, and noise requirements before pouring a pad.

Carbon monoxide safety is non-negotiable. Keep portables outdoors—never in garages, basements, or enclosed porches—and aim exhaust away from living spaces. Install CO alarms on every level of your home and test them seasonally. Add a small preparedness kit near the generator: spare air filters, oil and funnel, spark plug, an approved fuel container if applicable, and a laminated quick-start checklist. Simple but effective protections include:

– A weather-appropriate cover or enclosure designed for ventilation and rain shedding

– Lockable, code-compliant fuel storage with clear separation from ignition sources

– Conduit and fittings rated for outdoor use, with drip loops to deter moisture ingress

Each item tightens the safety net, turning a potential hazard into a controlled, predictable system.

Transfer Switches and Electrical Integration

The heart of a safe installation is proper transfer equipment that prevents backfeed into the utility. A transfer switch selects the source feeding your circuits—utility or generator—so that only one is connected at a time. Options range from manual switches feeding a small “critical loads” subpanel to service-entrance-rated automatic transfer switches that handle an entire building. Interlock kits, where allowed, mechanically prevent the main breaker and generator backfeed breaker from being on simultaneously and can be a cost-effective method for selective whole-panel operation, though they require manual load management during an outage.

When choosing your path, consider:

– Which circuits matter most (heat blower, fridge, sump, essential lights, internet, medical devices)

– The available generator output (120 V only, or 120/240 V split-phase), which affects heavy loads like well pumps or large AC

– Manual vs automatic operation preferences, and whether unattended transfer is important

– Space in your service equipment and compatibility with rated enclosures and breakers

A manual critical-load subpanel simplifies priorities, while an automatic service-entrance solution provides hands-off reliability for frequent outages.

Electrical details deserve care. Conductor size must match breaker protection and anticipated current; for example, a 30-amp feeder typically uses 10 AWG copper in many jurisdictions, while a 50-amp feeder may require 6 AWG copper—always verify with local code tables and temperature ratings. Grounding and bonding depend on system classification: if the generator is a separately derived system, the neutral is switched and bonded at the appropriate location; if not, neutral remains solidly connected and the generator neutral is isolated. Portable generators with built-in GFCI receptacles can trip when connected incorrectly; ensure the transfer device and neutral scheme are compatible. Balance loads across the two legs of 120/240 V to minimize voltage sag and heating. Label everything—both at the panel and at the generator inlet—so operation under stress is intuitive. The theme is simple: crisp isolation, correct conductor sizing, and clear labeling prevent both nuisance issues and dangerous faults.

Step-by-Step Installation Process and Commissioning

Good installations follow a steady rhythm. Start by confirming permits and marking utilities before digging. Prepare the pad: a 4-inch concrete slab or compacted gravel base, level and larger than the generator footprint, helps with drainage and service access. Set the unit or inlet box, anchor according to instructions, and route appropriately rated conduit from the transfer switch to the generator location with gentle sweeps to protect conductors. Weatherproof all penetrations, add drip loops, and use anti-oxidant on aluminum terminations where required. For fuel, follow the applicable fuel gas or liquid fuel code: rigid piping with proper supports, sediment traps where specified, and a shutoff valve in an accessible location. Perform leak checks with a manometer or approved leak-detection solution; never rely solely on smell.

Inside at the electrical, de-energize, lockout, and verify absence of voltage. Install the transfer switch or interlock device per listing and instructions. Move selected circuits to the critical-loads panel if using that strategy, keeping motors and heating loads distributed to avoid nuisance trips. Torque lugs to specification—loose connections cause heat and intermittent faults. Terminate conductors with clear labels: “Generator feeder,” “Utility supply,” and circuit names that match room-level labels. If installing an outdoor inlet, use a twist-lock configuration suited to the amperage and voltage of your generator, and weatherproof the box. Finally, install signage at the service equipment stating that multiple power sources exist; inspectors look for legible, durable labels.

Commissioning is where the system proves itself. With the utility on, verify normal operation. Then simulate an outage: for automatic systems, open the utility source and observe transfer, startup time, and stabilization; for manual systems, follow the checklist to switch sources. Under generator power, measure voltage and frequency—typical targets are about 120/240 V and near 60 Hz—and turn on priority loads one by one. Listen for engine labor, watch for flicker, and feel for excessive vibration. Let the system run long enough to reach operating temperature. After retransfer, review any error codes, re-torque as required after the first few hours, and log key data:

– Runtime hours and oil level

– Voltage/frequency readings at light and moderate load

– Fuel pressure (if applicable) and any observed leaks

This log becomes your maintenance compass, telling the story of the system over seasons.

Costs, Maintenance, and Long-Term Reliability

Total cost of ownership includes more than the generator. Budget for transfer equipment, permits, pad materials, fuel plumbing, electrical labor, and inspection fees. Portable setups with a manual transfer device typically land at a modest entry point, while fully automatic whole-home systems can be several times higher due to labor and fuel work. Fuel costs vary by region and load factor: as rough planning figures, a 5 kW gasoline generator might consume around 0.5–0.7 gallons per hour at 50% load; a 7–10 kW propane unit may use roughly 1–2 gallons of propane per hour at moderate load; a 20 kW natural gas standby can use approximately 200–300 cubic feet per hour at half load. Use these to estimate runtime and refueling cadence. For example, a 250-gallon propane tank (with about 200 gallons usable) running at 2 gallons per hour offers near 100 hours of operation—about four days—before refill.

Preventive maintenance keeps the quiet heartbeat of your home steady. Common intervals include oil and filter changes every 50–100 hours for portables and annually or 150–200 hours for many standby units, plus periodic air filter and spark plug service. Exercise automatic generators monthly for 10–15 minutes to circulate oil and identify issues early. Keep batteries charged and replace them every 3–5 years; weak starting batteries are a frequent cause of no-start events. For liquid fuels, use stabilizer for gasoline and rotate stock; for diesel, prevent microbial growth with biocide and monitor water contamination. Check fasteners and mounting points annually; vibration slowly loosens even the most carefully torqued hardware.

Reliability is a chain, and the weak link often isn’t the generator at all. Common pitfalls include ignoring permits, undersizing conductors, skipping CO detectors, placing units too close to openings, and failing to test under real load. Avoid using household extension cords through doors and windows for long-term operation; permanent wiring with a transfer device is safer and more convenient. Never backfeed a panel through a dryer outlet or similar—this is dangerous and typically illegal. Instead, rely on properly rated inlets and listed transfer equipment. Create a seasonal checklist:

– Before storm season: test transfer, top off fuel, clear vegetation, update labels

– During extended outages: monitor oil level and temperature, rotate loads to avoid overload

– After outages: inspect for leaks, log runtime hours, schedule maintenance

Over time, these habits transform a generator from an emergency gadget into a quietly reliable utility, ready to light your home’s lantern when the grid goes dark.