Find more Electrician Services

Electrician services touch nearly every corner of modern life, from the outlet that charges your phone to the panel quietly balancing loads behind a closet door. Reliable electrical work keeps people safe, appliances efficient, and buildings code‑compliant—benefits that compound year after year. Whether you manage a busy shop or a cozy townhouse, understanding how these services are organized helps you choose confidently, budget wisely, and avoid hassles.

Outline:

– Understanding electrician services: scope, licensing, and the service call

– Residential vs commercial: differences in power, materials, and project planning

– Safety, codes, and permits: what protects you and your property

– Pricing, estimates, and contracts: how to compare offers

– Choosing a pro and next steps: upgrades that add value

What Electricians Do: Scope, Specializations, and Value

Electrician services cover far more than fixing a tripped breaker. Professionals install new systems, modernize older wiring, troubleshoot faults, and maintain equipment so it performs safely and efficiently. At a high level, their work clusters into four areas that span the life cycle of a building: installation, maintenance, repair, and upgrades. Each area requires familiarity with codes, load calculations, grounding and bonding methods, and testing instruments that verify both performance and safety. The result is not just functioning lights and outlets, but a resilient electrical ecosystem designed to handle today’s devices and tomorrow’s demands.

Here’s how the scope typically breaks down in practical terms:

– Installations: new circuits, switchboards and panels, lighting layouts, receptacles, dedicated lines for large appliances or workspace equipment

– Repairs: replacing damaged conductors, correcting reversed polarity or open grounds, solving nuisance tripping, addressing overheated connections and loose terminations

– Preventive maintenance: infrared scans to detect hot spots, torque checks on lugs, breaker testing, GFCI and AFCI verification, surge protection inspection

– Upgrades: panel capacity increases, whole‑home surge protection, LED retrofits, smart controls, EV‑ready circuits, generator transfer equipment

A standard service call often starts with a clear problem statement (“this outlet is warm,” “the lights dim when the microwave runs”) and a visual inspection: panel labeling, breaker sizes, conductor conditions, and grounding paths. Next come measurements and tests—voltage checks, continuity, and sometimes insulation resistance screening for aging cables. Good technicians document findings and explain options in plain language. That might include a quick repair for a single device, a recommended circuit split to reduce overloads, or a phased plan for broader improvements. The value becomes obvious in avoided downtime, reduced energy waste, and most importantly, reduced risk of shock and fire. A small upgrade—like installing GFCI protection in wet areas or arc‑fault protection in living spaces—can meaningfully lower the chance of dangerous events while meeting contemporary standards for safety.

For property managers and homeowners alike, specialization matters. Some electricians focus on service upgrades and heavy power work, others on lighting design and controls, and others on diagnostics and maintenance programs. Selecting a provider with a track record in projects similar to yours increases efficiency and helps ensure the finished work integrates cleanly with existing systems.

Residential vs. Commercial Services: Comparing Needs and Approaches

Residential and commercial electrical work share the same physics and safety fundamentals, but the priorities and methods can diverge in telling ways. In homes, circuits often serve comfort, convenience, and lifestyle upgrades—kitchens with multiple small appliances, home offices with sensitive electronics, outdoor living spaces with lighting and weatherproof outlets. Loads are distributed among 120/240‑volt systems in many regions, with numerous branch circuits feeding lighting, general‑use receptacles, and dedicated lines for heavy appliances. Materials may include nonmetallic sheathed cable within walls, weather‑rated boxes outdoors, and tamper‑resistant receptacles for family safety.

Commercial settings typically emphasize reliability under continuous use, capacity for growth, and clear maintenance access. You’ll often see more extensive use of raceway systems, larger panels, three‑phase power where available, and lighting controls tuned for occupancy and daylight. The stakes can be higher: an unexpected outage can halt sales, stop production, or disrupt essential services. That’s why commercial work often adds layers of redundancy, labeling, and documentation beyond what a home needs. Scheduling is also different; many commercial projects happen after hours to keep customers and staff undisturbed.

Key contrasts that shape project planning:

– Design objectives: homes favor comfort, aesthetics, and quiet operation; commercial spaces prioritize uptime, code‑driven egress lighting, and scalable power distribution

– Materials and methods: residential may use cable runs inside cavities; commercial often uses conduit, accessible junction points, and modular fixtures for ease of service

– Controls: smart dimmers and scene controls in homes; networked lighting and building management integration in offices or shops

– Inspection and record‑keeping: both must meet code, but commercial projects commonly require more detailed as‑built drawings, labeling, and maintenance schedules

Examples clarify the differences. A kitchen renovation might add multiple small‑appliance circuits, GFCI protection, and task lighting that eliminates shadows on work surfaces. A small bakery, by contrast, could need a service capacity evaluation for ovens and mixers, dedicated circuits with appropriate receptacle ratings, and lighting that meets light‑level targets while keeping energy costs predictable. In both cases, a skilled electrician maps the load, selects materials suited to the environment, and sequences the work to minimize disruption—weekend cutovers for a storefront, or brief shutdowns at home coordinated around family routines.

Safety, Codes, and Permits: How Compliance Protects You

Electrical codes are not red tape; they are a safety net woven from decades of lessons learned. Permits and inspections exist to catch hazards before they have a chance to cause shock, smoke, or fire. When an electrician pulls a permit, the project receives oversight from the local authority having jurisdiction, creating a clear record that the installation meets current requirements. That record simplifies insurance claims, improves resale confidence, and helps future technicians understand what was installed and why.

Common safety elements you may encounter include ground‑fault protection in kitchens, bathrooms, outdoors, and other damp or wet locations; arc‑fault protection in living and sleeping areas; properly sized overcurrent protection that matches conductor ampacity; and robust grounding and bonding to provide a low‑impedance path that clears faults quickly. Smoke and carbon‑monoxide alarms, while often on separate low‑voltage or line‑voltage circuits, are integral to a home’s life‑safety system and should be tested regularly. In commercial spaces, emergency lighting and exit signage are critical, along with selective coordination of protective devices to isolate faults without blacking out entire areas.

Quick checks that pay off:

– Warm devices, discolored cover plates, or buzzing sounds suggest loose connections or overloads that need investigation

– Frequently tripping breakers may indicate an undersized circuit, a failing device, or a wiring irregularity

– Extension cords used as permanent wiring are a red flag; adding a properly installed receptacle is the safer, code‑compliant solution

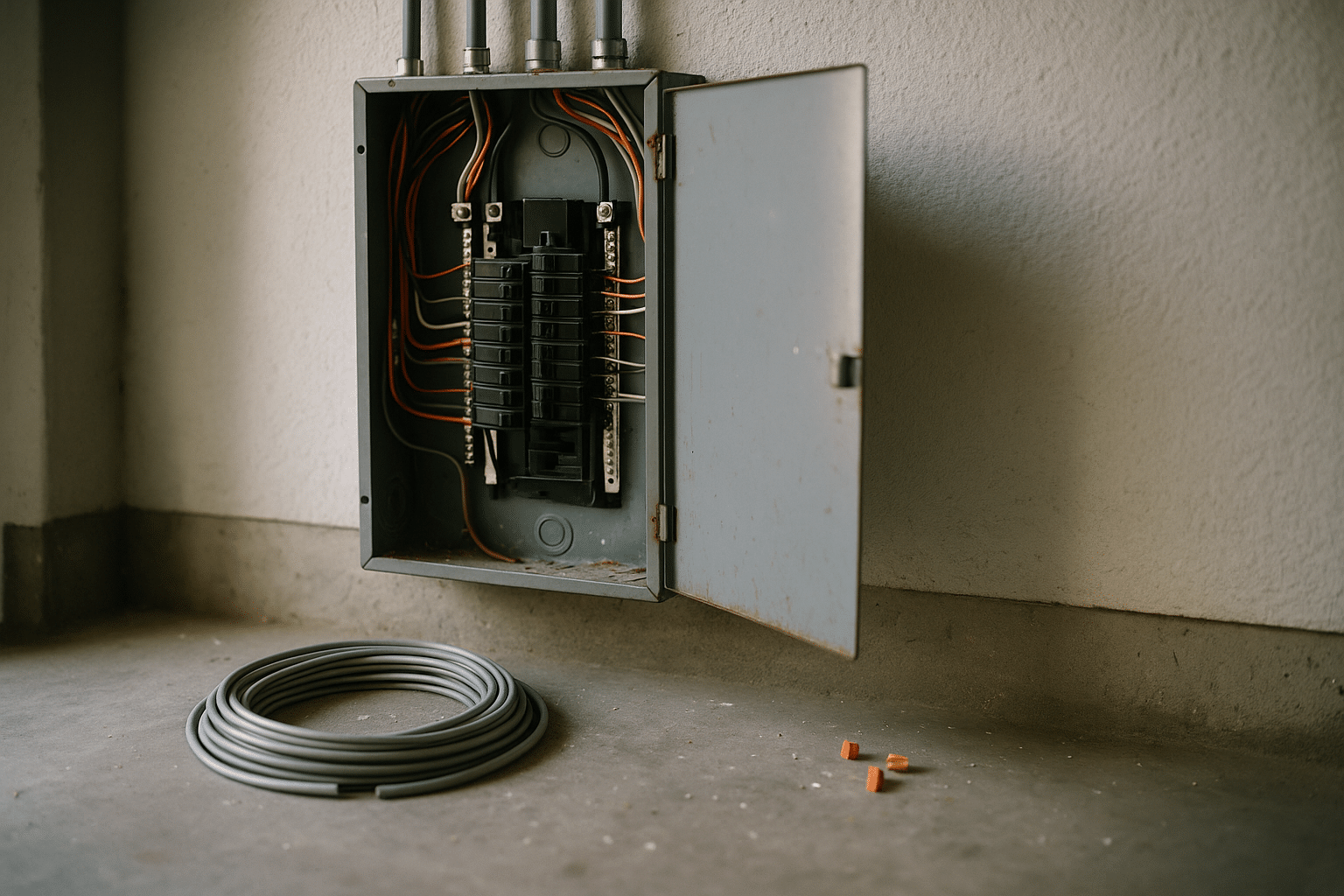

– Rust in panels or boxes hints at moisture intrusion; addressing the source protects both people and equipment

Testing is where professionalism shows. Electricians rely on calibrated instruments—voltage and continuity testers, clamp meters, sometimes insulation resistance testers—to verify that conductors are intact, connections are tight, and protective devices operate as intended. Documentation matters: photos of junctions before they are covered, panel schedules updated to match reality, and labels that make future service straightforward. While many small tasks seem approachable, working on energized equipment is hazardous; reputable professionals follow lockout and verification procedures and never rely on assumptions. Compliance is not merely about passing an inspection—it is about building systems that fail safely, alert predictably, and recover quickly.

Pricing, Estimates, and Contracts: Paying for Quality

Electrical pricing varies by region, project complexity, and scheduling. Some work is billed hourly, often with a minimum service charge to cover travel and setup time; other work is offered at a fixed price once the scope is clear. Small tasks—replacing a device, troubleshooting a single circuit—may be completed within that minimum. Larger jobs, like panel changes or whole‑room rewires, usually receive written estimates that break out labor, materials, permits, and disposal. Transparent proposals help you compare apples to apples and reduce surprises once the dust settles.

Expect estimates to reflect:

– Labor: experience, certifications, and the number of technicians required for safe handling and efficient workflow

– Materials: copper prices, fixture quality, device ratings, and whether specialty components are needed

– Access conditions: attic or crawlspace work, finished surfaces that require careful patching, or occupied spaces that demand off‑hours scheduling

– Risk and contingency: unknowns behind walls, existing code violations that must be corrected, or coordination with other trades

Fixed‑price proposals shine when the scope is well defined; time‑and‑materials can be fairer when the conditions are truly unknown. Either way, a clear contract protects everyone. Look for line items describing the scope, exclusions, permit responsibilities, cleanup, patching, inspection scheduling, and warranty terms. Many reputable providers offer workmanship warranties for a defined period and manufacturer warranties for devices. Deposit policies should be reasonable and tied to milestones, with final payment due after completion and sign‑off. Red flags include vague descriptions, unusually low pricing that ignores permits, or requests for large upfront payments disconnected from material purchases or phases.

To avoid missteps, gather two or three detailed quotes and compare not just totals but approaches. One team might propose splitting overloaded circuits; another might recommend a service capacity upgrade if you plan heat‑pump additions or vehicle charging. Both could be valid—your choice should align with immediate needs and long‑term plans. When proposals describe options with pros and cons, you gain the context to choose a solution that balances reliability, cost, and future flexibility.

Choosing the Right Electrician and Next Steps: Upgrades That Deliver

Selecting an electrician is part technical evaluation, part communication test. Licenses and insurance are table stakes, but references, recent project photos, and clear explanations are equally revealing. A knowledgeable professional listens to your goals, asks practical questions about usage patterns, and suggests phased solutions when budgets are tight. They also set expectations about access, dust control, and scheduling, so daily life or business operations stay on track. Think of the process like tuning an instrument: the right craftsperson brings systems into harmony, reduces background “noise” like dimming and nuisance trips, and leaves room to add new features without discord.

Upgrades worth considering for many properties:

– LED lighting and quality dimmers: lower energy use, less heat, and better control of ambiance or task lighting

– Whole‑home or service‑level surge protection: a layer of defense for sensitive electronics and high‑efficiency appliances

– Smart controls: occupancy sensors in low‑traffic areas, timers for exterior lights, and scenes that adjust multiple circuits with one command

– Capacity planning: evaluating panel space and service size before adding large loads such as heat pumps, workshop tools, or vehicle charging

– Outdoor and garage improvements: weather‑rated outlets, improved task lighting, and dedicated circuits for equipment

As you move forward, organize your decision‑making:

– Define outcomes: brighter workspace, safer wet areas, space for future electrification, or reduced utility costs

– Document the existing system: panel photos with circuit numbers, counts of fixtures and devices, and notes on problem areas

– Request clear proposals: alternate options with costs, timelines, and code considerations spelled out

– Plan for the future: even if you defer an upgrade, pre‑wiring or conduit can lower total cost later

Conclusion for property owners and managers: safe, efficient electrical systems do not happen by accident—they are built through informed choices and qualified workmanship. Start with a frank conversation about needs, review detailed proposals, and select a provider who demonstrates both technical skill and clarity. The payoff is tangible: steadier lighting, quieter panels, fewer outages, and a path ready for modern comforts and electrification goals. With a well‑planned approach, you’ll gain reliability today and the flexibility to adapt tomorrow without tearing things apart to start over.