Find more Electrician Services

Outline:

– Scope of electrician services and when to call

– Safety, codes, and risk management

– Service types across residential, commercial, and industrial

– Pricing models, estimates, and value

– Hiring checklist, maintenance, and next steps

Scope of Electrician Services and When to Call

Electricity is the quiet river in your walls—reliable until it swells, slows, or splits. Electrician services exist to keep that flow safe, efficient, and ready for today’s devices as well as tomorrow’s upgrades. At a high level, licensed electricians design, install, maintain, and repair electrical systems that power lighting, appliances, networking gear, machinery, and life‑safety equipment. Their work spans early planning for new builds, troubleshooting for existing spaces, and thoughtful modernization to reduce energy use and increase resilience. Because electrical issues can escalate quickly, understanding when to call a professional protects both property and people.

Consider the breadth of typical projects:

– New circuits for kitchens, workshops, home offices, or specialty equipment

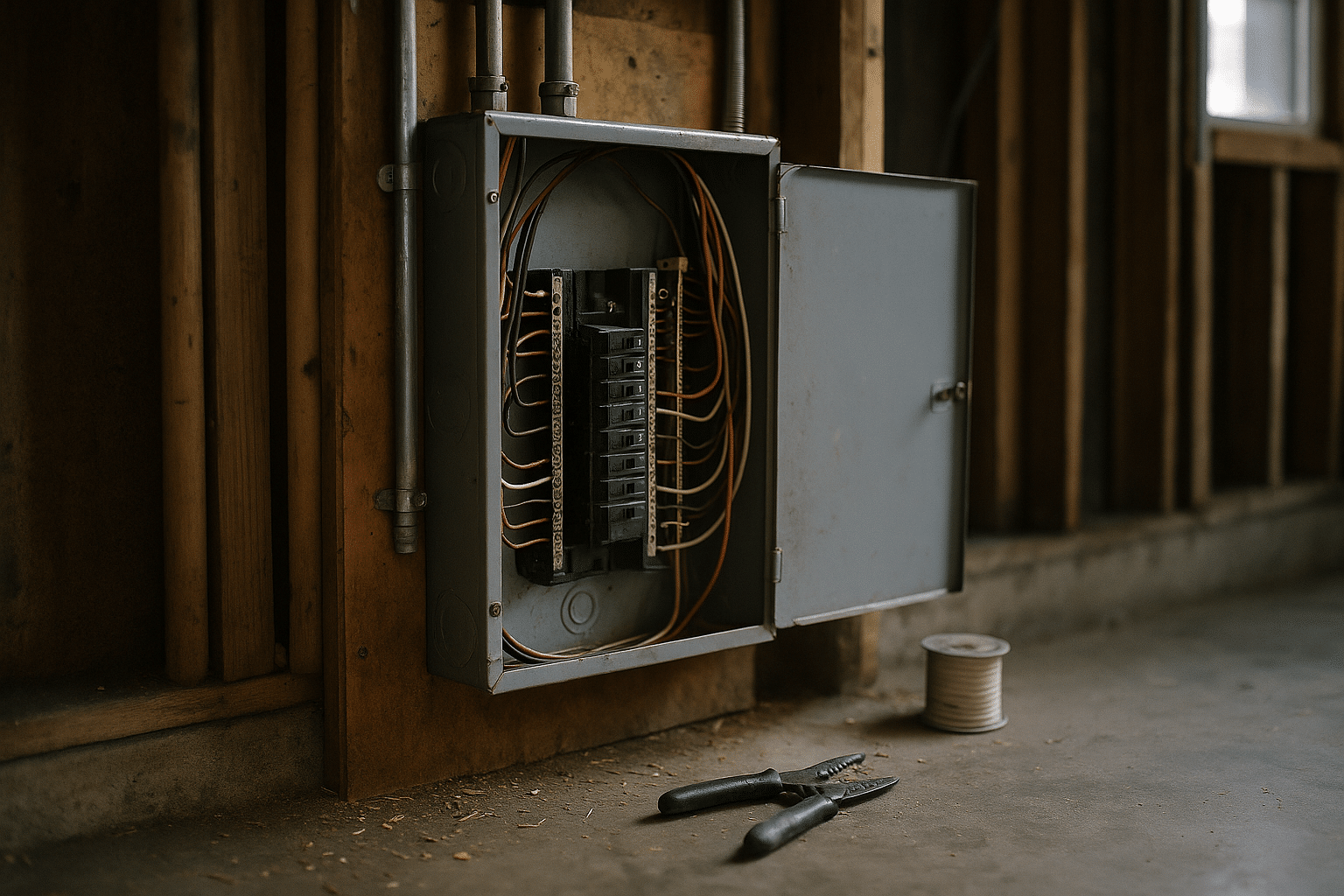

– Panel upgrades to support added loads like heating, cooling, or vehicle charging

– Lighting design, including dimming, task lighting, and exterior illumination

– Outlet additions, relocation, and protection with ground‑fault or arc‑fault devices

– Whole‑home surge protection and bonding for metal piping or structures

– Backup power solutions using transfer equipment and standby systems

Not every symptom is dramatic. Warning signs include warm faceplates, a faint buzzing at a breaker, tripping under light usage, or lights that dim whenever a motor starts. A professional will trace root causes, which may involve overloaded circuits, loose terminations, outdated aluminum branch wiring, or undersized service capacity. Unlike quick fixes, a systematic approach documents findings, references local code requirements, and proposes options with clear trade‑offs in cost, disruption, and long‑term reliability. Proactive calls are wise before a renovation, when moving heavy equipment, or after adding multiple high‑draw devices. Waiting until a failure occurs often raises expense due to emergency scheduling, potential damage, or the need to open finished surfaces. If electricity is the infrastructure you rarely see, the electrician is the guide who keeps your paths mapped and safe.

Safety, Codes, and Risk Management

Safety sits at the heart of every electrical decision. Local electrical codes—typically based on national standards—exist because the risks of shock and fire are real, even in modern buildings. Authorities adopt updated rules every few years, integrating lessons from incident data, product changes, and research. For homeowners and facility managers, the practical takeaway is clear: compliant work is not just about passing inspection; it measurably reduces hazards and can improve insurance standing. Industry and public safety reports consistently attribute thousands of structure fires each year to electrical distribution issues, with wiring faults, overloaded circuits, and aging components among the common sources.

Risk management blends equipment choices with installation methods. Key protective devices include:

– Ground‑fault protection in wet or damp areas to reduce shock risk

– Arc‑fault protection on many living‑area circuits to minimize ignition from damaged conductors

– Surge protection at the service and at sensitive equipment to limit transient overvoltage

– Proper bonding and grounding to stabilize voltage and clear faults quickly

Beyond devices, safe installations hinge on fundamentals: correct conductor sizing, secure terminations, adequate enclosure fill, and working clearances around equipment. Permits and inspections create accountability, ensuring an independent check before walls close or systems energize. A licensed electrician will explain what requires a permit in your jurisdiction, how long approvals typically take, and what to expect during rough‑in and final inspections. In older buildings, safety upgrades often start with a panel evaluation, replacement of brittle insulation or non‑compliant splices, and adding protection where none existed—particularly for kitchens, bathrooms, laundry areas, garages, and outdoor outlets. For businesses, risk management extends to emergency lighting, illuminated egress paths, equipment lockout points, and documented maintenance schedules that satisfy workplace safety standards. The most valuable mindset is preventive: establish a baseline assessment, remedy the obvious hazards, then plan sequenced improvements that fit your budget and calendar. With that strategy, compliance becomes a by‑product of doing the right things in the right order.

Residential, Commercial, and Industrial Services Compared

Although the principles of voltage, current, and resistance never change, the context does. Residential work focuses on comfort, convenience, and aesthetics, while commercial projects prioritize reliability, lighting quality, and layout flexibility for changing tenants. Industrial environments emphasize power quality, motor control, and uptime, often under more demanding environmental conditions. Understanding these differences helps you match expectations and ask sharper questions during estimates.

Residential services typically involve:

– Load calculations for additions and kitchen remodels

– Panel replacements and service capacity upgrades

– Lighting plans that balance ambient, task, and accent layers

– Protection devices and tamper‑resistant receptacles where required

– Low‑voltage runs for networking, sensors, and entertainment

Commercial work ranges from small retail build‑outs to multi‑level offices. Typical tasks include new feeders for tenant spaces, distribution changes to support relocated workstations, high‑efficiency lighting with controls, and signage circuits. Projects often require coordination with property management, after‑hours cutovers, and staged inspections to limit downtime. Documentation matters more, including as‑built drawings, circuit directories that match panel schedules, and maintenance logs for life‑safety systems. Industrial services go further, integrating motor starters, variable frequency drives, control panels, equipment interlocks, and robust grounding to handle fault energy. Cable routing must account for vibration, heat, chemicals, and physical protection. Testing may include insulation resistance, thermography to spot loose lugs, and power quality measurements to detect harmonics or voltage sags that can disrupt processes.

Timelines and tools differ as well. A residential lighting retrofit may finish in a day, while a commercial control upgrade might span nights and weekends to keep operations running. Industrial shutdowns are orchestrated like small productions, with lockout procedures, spare parts on hand, and clear rollback plans. Across all sectors, a skilled electrician communicates constraints early, sequences work to reduce disruption, and documents what changed and why. Those habits turn complex projects into predictable experiences.

Pricing, Estimates, and Value: How Electricians Structure Costs

Transparent pricing helps you compare options without guesswork. Electricians commonly use one of two approaches: time‑and‑materials or flat‑rate pricing. Time‑and‑materials bills actual hours plus parts, making sense for open‑ended troubleshooting or projects with uncertain conditions behind walls. Flat‑rate pricing offers a predetermined amount for a defined scope—ideal when tasks are well specified. In both cases, travel, permits, and disposal fees may apply, and emergency or after‑hours calls often carry a premium due to overtime and scheduling constraints.

Cost drivers include:

– Scope complexity (simple receptacle vs. subpanel with multiple circuits)

– Access (finished spaces vs. open framing; attic/crawlspace work; ceiling height)

– Materials (copper conductor size, device quality, and enclosure ratings)

– Safety requirements (protection devices, bonding, labeling, and testing)

– Coordination (other trades, off‑hours cutovers, and inspection windows)

Consider a practical comparison. Suppose you need two new kitchen circuits, six recessed lights with dimming, and a service check. A flat‑rate proposal might bundle labor and standard materials, with allowances for patching excluded. A time‑and‑materials proposal might estimate a range—say, two technicians for a day and a half—clarifying hourly rates and part markups. If the attic is unobstructed and the panel has capacity, the lower end of the range may apply; if joist bays are blocked or the panel is at capacity, added time and parts push the total upward. Value emerges where scope is explicit: clear drawings or photos, notes on finishes to protect, and agreement on device styles reduce rework and change orders.

To evaluate proposals fairly, ask for itemized scope, assumptions, and exclusions. Request lead times for special‑order materials and clarify warranty terms for both labor and products. If your project touches life‑safety systems, ensure testing and commissioning are included. Total cost of ownership matters too; higher‑quality devices and thoughtful circuit layout can reduce nuisance trips, improve energy performance, and lower maintenance over time. A well‑explained estimate is more than a number—it is a plan you can hold accountable.

Hiring Checklist, Maintenance Plan, and Conclusion

Choosing an electrician is part research, part relationship. You want technical skill, reliable scheduling, and communication that makes complex topics understandable. Start with licensure that matches your project type, active insurance, and a track record of code‑compliant work. Then look for clarity: detailed proposals, clean circuit directories, and job photos that document progress. References from similar projects are valuable; a tidy residential retrofit calls for a different touch than a production floor shutdown, even if both demand the same core knowledge.

Use this concise checklist:

– Verify license class and insurance coverage appropriate to your scope

– Confirm permit responsibilities and anticipated inspection milestones

– Ask how your walls, floors, and furnishings will be protected

– Request a written scope with assumptions, exclusions, and timeline

– Clarify warranty terms and response times for callbacks

– Discuss options for surge protection, arc/ground‑fault devices, and labeling

– Schedule a walk‑through for final testing and orientation

Maintenance is where safety and savings compound. A yearly visual inspection can catch discoloration at outlets, loose cover plates, or corrosion in outdoor enclosures. For larger facilities, plan periodic testing: torque checks on lugs, thermal scanning under load, and verification of protective device operation. Keep an updated circuit directory and annotate it after every change; that single habit shortens future diagnostics. After storms or renovations, schedule a quick health check, especially if sensitive electronics or critical equipment are in play. If you added high‑draw loads—heating, data racks, or charging equipment—confirm service capacity and balance across phases where applicable.

Conclusion: Electrician services are less a one‑time fix and more an ongoing partnership with the systems that power your life and work. With a sound plan, clear communication, and documented choices, you can align safety, performance, and cost without surprises. Whether you are lighting a studio, modernizing a kitchen, or preparing a shop floor for new machinery, a qualified professional helps you move from uncertainty to confidence—quietly, safely, and with an eye toward the future you are building.