Learn about House Demolition

Where House Demolition Begins: Outline, Purpose, and Early Decisions

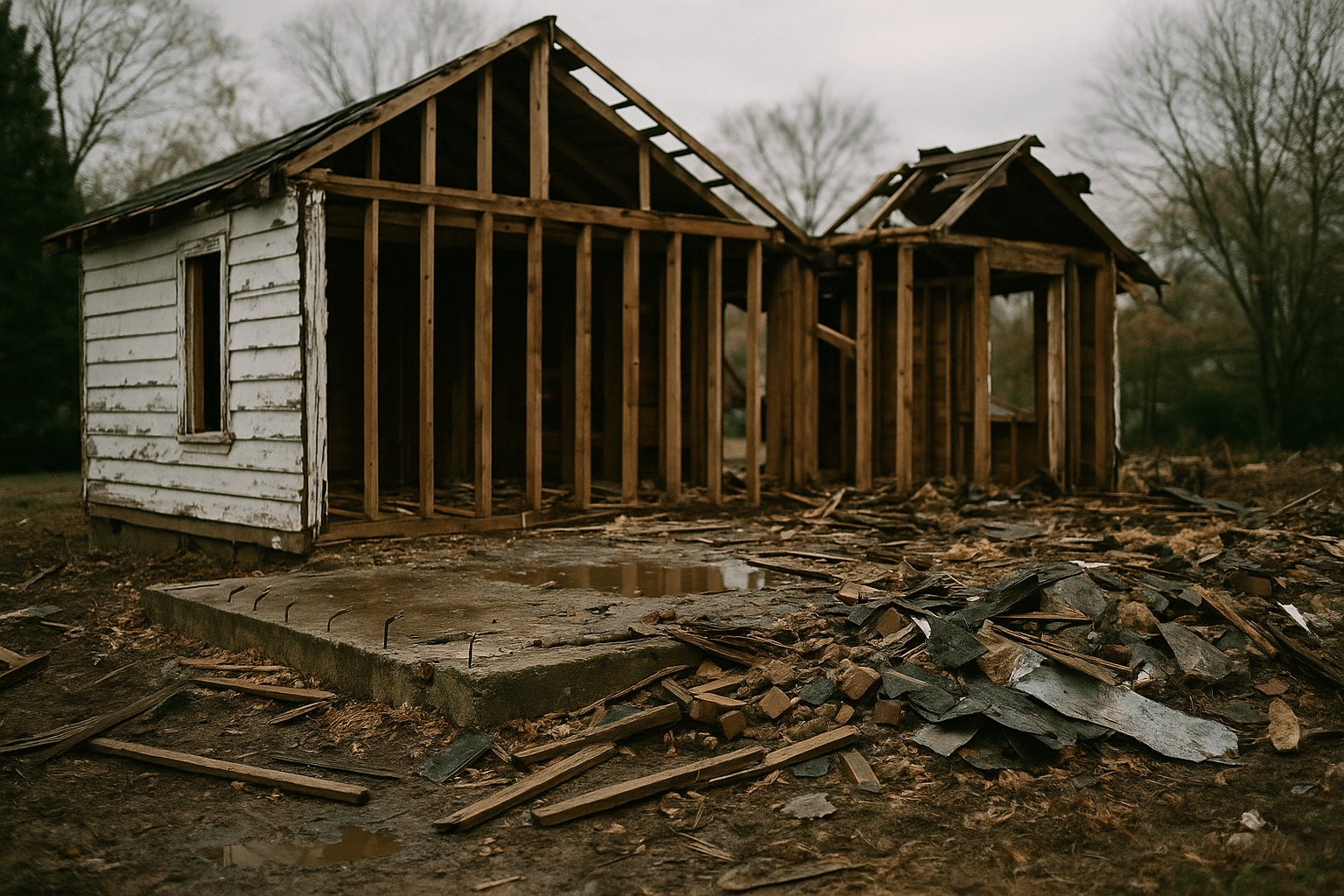

Demolishing a house is not the quick smash-and-haul job it sometimes appears to be. It’s a project with legal, environmental, financial, and safety layers that must align before the first wall comes down. The smarter approach starts with clear intent—are you removing a structure for new construction, mitigating structural hazards, or reclaiming a site after storm damage? Getting intent right shapes everything from the method you choose to the sequence of permits and inspections. To frame this guide, here’s a quick outline of what follows and why it matters for homeowners and property managers:

– Methods compared: mechanical, deconstruction, and specialized techniques, with timelines and cost ranges

– Permits and utilities: approvals, inspections, and shutoffs to keep crews and neighbors safe

– Environmental stewardship: salvage, recycling, and dust control that reduce costs and impacts

– Budget, scheduling, and team selection: how to align scope, contractor capability, and site risks

– Conclusion and next steps: a practical checklist to turn plans into action

Why outline first? Because demolition is a sequence activity: every downstream step depends on upstream readiness. For example, choosing a method without checking for hazardous materials can stall work and inflate costs when an inspector flags lead paint, asbestos, or hidden fuel tanks. Similarly, tearing down a structure without utility disconnect confirmations can create serious hazards and legal exposure. Early decisions also influence cost efficiency. Mechanical demolition can be faster and often cheaper per square foot, but selective deconstruction can reclaim valuable materials and reduce landfill fees. A clear plan turns trade-offs into savings instead of surprises.

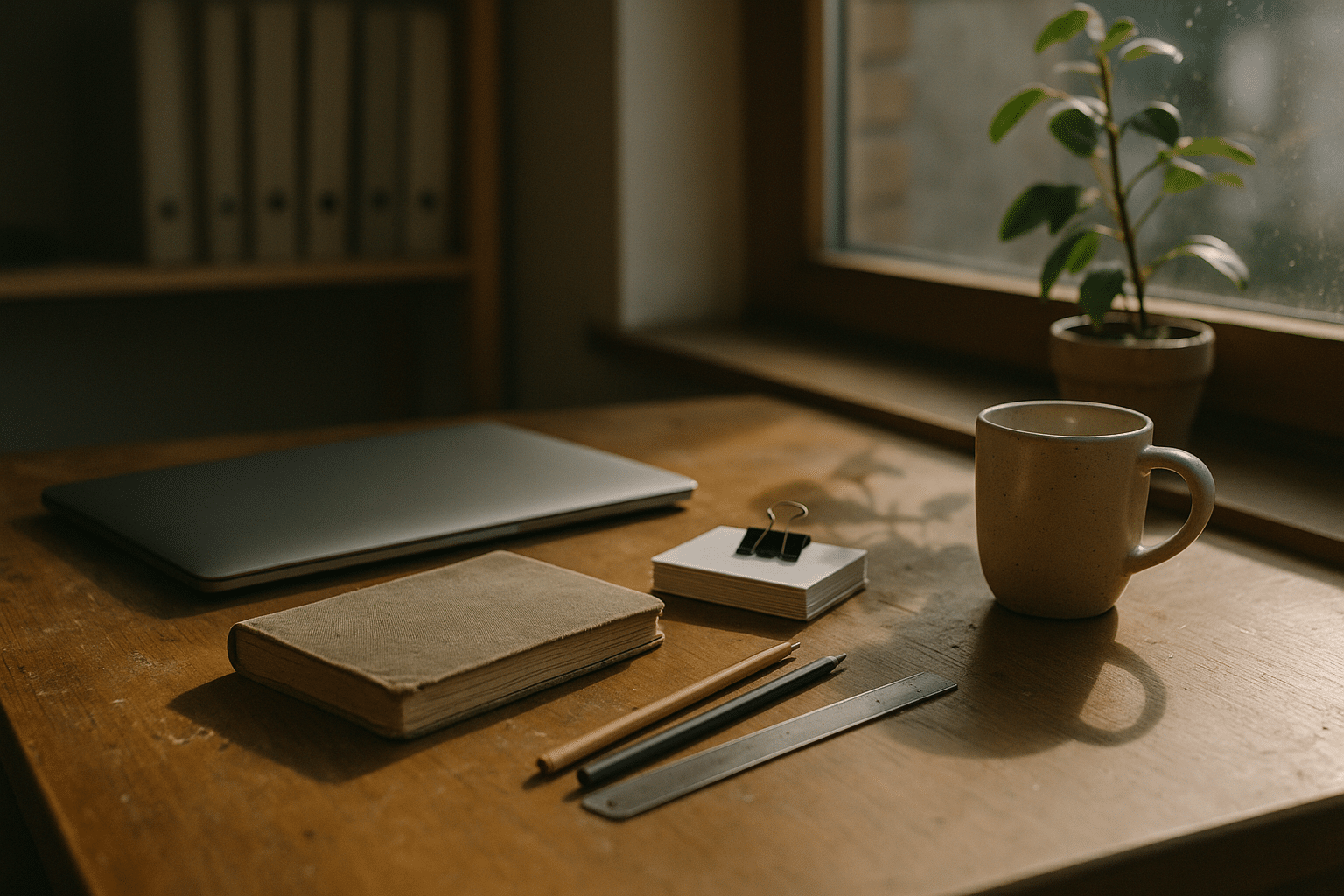

Before requesting quotes, assemble a project brief that states the property address, square footage, age of the structure, site access constraints, nearby trees or fencing, and the desired end state (e.g., rough grade only, or backfill and compact for a new slab). Photographs, a sketch of the lot, and any previous inspection reports help prospective contractors provide accurate estimates and flag risks early. Practical prep steps include:

– Commission a pre-demolition survey to identify hazardous materials and structural weaknesses

– Contact utility providers for written disconnect confirmations for electricity, gas, water, sewer, and telecom

– Note neighbor proximity, school zones, and traffic patterns that may affect work hours and dust control

– Decide what you want to salvage or donate before crews mobilize, and set aside access routes for reuse partners

Finally, accept that demolition is both technical and civic. The work must protect public safety, respect local noise and dust standards, and manage debris responsibly. With a roadmap in hand, you’ll negotiate more confidently, compare apples to apples in bids, and keep your schedule moving toward the build or landscape you have in mind.

Demolition Methods Compared: Mechanical, Deconstruction, and Specialized Options

There are three widely used approaches for house demolition, each defined by speed, cost, and material recovery: mechanical demolition, deconstruction, and specialized techniques such as partial structural dismantling and the rare residential implosion. The right method balances site constraints, budget, and reuse goals.

Mechanical demolition uses heavy equipment to bring down the structure quickly, then sorts debris for hauling. It is common for standard wood-frame homes with straightforward access. Typical production rates can clear an average single-family home in one to three days once utilities and permits are in order. Cost varies by region and complexity, but many homeowners see ranges roughly from the mid-single digits to low double digits per square foot, with added fees for tight access, steep lots, or heavy foundations. Advantages include speed, predictable scheduling, and lower labor hours. Trade-offs include lower salvage rates and potentially higher landfill fees unless sorting is emphasized.

Deconstruction takes a building apart piece by piece, aiming for maximum salvage. Crews remove fixtures, flooring, cabinetry, doors, windows, beams, and sometimes sheathing, preserving components for resale or donation. This method is slower—often several days to a few weeks depending on size and complexity—but can recover valuable materials. In markets with strong reuse networks, reclaimed lumber, antique brick, and architectural elements can offset a meaningful fraction of project cost, and donation receipts may offer tax benefits where applicable. Advantages include high diversion rates and character material recovery; trade-offs include higher labor costs and longer schedules.

Specialized methods cover partial structural dismantling, hand demolition in dense urban sites, and, very rarely for residential, controlled explosive work. Implosion is almost never appropriate for single homes due to proximity to neighbors, permitting constraints, and risk tolerance, but selective dismantling is useful when preserving portions of a building, such as a historic façade or foundation. In these cases, crews combine hand work with small equipment, emphasizing protection for elements that must remain.

Choosing among methods involves weighing several criteria:

– Site access and neighbors: narrow streets, overhead wires, and close lot lines favor smaller equipment or hand work

– Structure type: masonry and reinforced concrete require different tooling than light wood framing

– Salvage goals: high-value finishes and large-dimension lumber justify slower deconstruction

– Time constraints: compressed schedules favor mechanical approaches with robust sorting plans

– Environmental priorities: aggressive recycling and dust control may influence sequencing and equipment choice

A hybrid approach is common: start with a selective interior strip-out to harvest fixtures and metals, then finish with mechanical removal of the shell. This strategy captures much of the reuse value without turning the schedule upside down. When comparing bids, ask for method statements, anticipated diversion rates, and daily production targets to keep expectations realistic.

Permits, Utilities, and Safety Protocols That Keep Projects on Track

Permitting and utility coordination are the backbone of a safe, lawful demolition. Requirements vary by jurisdiction, but most authorities expect a demolition permit, proof of utility disconnects, a site plan, and sometimes erosion-control measures. In historic districts or environmentally sensitive zones, additional review boards may need to sign off. Skipping or compressing these steps invites stop-work orders, fines, or worse—the kind of delays that cost far more than any permit fee.

Start by contacting your local building department to confirm submittals and lead times. Many offices request:

– A completed application with owner authorization or contractor representation

– A demolition plan showing structure footprint, adjacent properties, and haul routes

– Confirmations of service shutoff for electricity, gas, water, sewer, and telecom from the providers

– Hazardous materials survey and, if needed, abatement documentation for asbestos, lead, or mold

– Traffic control and dust suppression plans when streets or sidewalks are affected

Utilities deserve special attention. Gas must be capped at the main; electrical services need to be disconnected at the pole or pedestal; water lines should be closed and verified to prevent leaks; and sewer laterals often require proper sealing to avoid infiltration. Telegraphic coordination is risky—get written confirmations. If a private well, septic tank, or underground storage tank exists, additional closure or removal procedures may apply, often under environmental oversight.

Safety protocols are standard practice, not add-ons. Expect fencing, clear signage, and defined exclusion zones. Crews should conduct daily briefings, verify equipment inspections, and maintain fire watch protocols when hot work is involved. Dust control, typically via water spray, reduces airborne particles, and wheel-wash or street-sweeping helps keep sediment off public roads. Noise windows, often limited to certain daytime hours, protect neighbors and reduce complaints that can jeopardize your schedule.

Hazards are best managed by anticipating them. Common risks include unstable walls, hidden chimneys within rooflines, post-tensioned slabs, and concealed voids under floors. A pre-demolition walk-through with the superintendent identifies these conditions and determines the order of removal to prevent sudden collapses. For example, leaving interior shear walls too long while cutting exterior supports can create unexpected load paths. The safest jobs follow a planned sequence and use spotters who maintain line-of-sight communication with operators.

Finally, keep documentation organized: permits posted, disconnect letters on-site, and inspection results filed. When the inspector arrives, a tidy site and clear paperwork signal competence, often resulting in faster approvals and fewer follow-up visits.

Environmental Stewardship: Salvage, Recycling, and Dust Control

Demolition can be a powerful sustainability opportunity when approached thoughtfully. Construction and demolition activities generate hundreds of millions of tons of material annually in large countries, yet a significant portion can be reused or recycled. Wood framing, metals, clean concrete, asphalt shingles, and unpainted brick often have second lives—reducing landfill demand and, in many markets, lowering disposal costs.

Start with a salvage plan that lists targets by category. High-return items frequently include doors, windows, flooring, cabinetry, dimensional lumber, fixtures, and non-ferrous metals. Many communities have reuse centers or donation partners that will schedule pick-ups if notified in advance. Concrete and masonry can be crushed into aggregate for backfill or road base; in some regions, mixed C&D facilities sort loads mechanically, achieving diversion rates above 70 percent for typical projects. Clarify with your contractor whether sorting will occur on-site or at a materials recovery facility to avoid misunderstandings.

Dust and noise management are environmental issues, too. Water misting at the point of impact keeps particulate levels down and protects adjacent properties. In dry or windy conditions, crews may pause during gusts or add additional hoses. Cover trucks before leaving the site, and consider track-out pads or wheel washes to prevent debris on public streets. If your area enforces air-quality standards, track compliance via daily logs and photographs that document water use and site cleanliness.

Hazardous materials require specialized handling. Asbestos-containing materials, lead-based paint, certain adhesives, and older electrical components may fall under strict rules. Only licensed abatement providers should remove and dispose of these materials, following chain-of-custody and manifest requirements to approved facilities. Proper abatement protects workers, neighbors, and future soil conditions, and it also prevents project shutdowns common when prohibited debris shows up at landfills.

Think lifecycle, not just landfill. Salvaged wood reduces demand for new lumber; reclaimed brick and fixtures add character to renovations; recycled metals conserve energy compared to virgin production. Even small choices add up. For instance, separating cardboard packaging from equipment deliveries or returning unused pallets to suppliers keeps material loops active. Ask your team for a diversion report at the end of the job—a simple summary of tonnage, destinations, and percentages—so you can quantify the project’s impact and share it with neighbors or future buyers.

In short, environmental stewardship is a practical strategy, not a luxury. It lowers hauling fees, builds goodwill, and, in some regions, satisfies green building requirements that may benefit future development on the site.

Conclusion and Next Steps for Homeowners: Budget, Scheduling, and Choosing the Right Team

With methods, permits, and environmental goals in mind, the final step is assembling a plan that fits your budget and timeline. Begin with a clear scope: identify which structures are coming down (house, detached garage, sheds, hardscape), the desired final grade, and any tree protection or fence preservation. Share this scope with at least three qualified contractors to receive comparable bids. Ask each for a line-item estimate that separates demolition, hauling, disposal or recycling, abatement allowances, site protection, and final grading. Transparent estimates help you compare more than just the bottom line.

Typical residential costs reflect local labor rates, disposal fees, access constraints, and the presence of hazardous materials. As a rough frame of reference, many projects land within a broad band when averaged per square foot, with higher figures for dense sites, masonry structures, or extensive abatement. Salvage and donation can offset a portion of costs; discuss which items are owner-claimed versus contractor-owned to avoid disputes. Consider a contingency—often 10 to 15 percent—for unforeseen conditions such as hidden wells, extra footing depth, or additional trucking due to moisture-laden debris.

Scheduling is equally important. A straightforward mechanical demolition may take two to seven working days once permits and utility disconnects are complete, with additional time needed for abatement and material recovery. Factor in lead times for permit reviews, which can range from a few days to several weeks, and build in buffer days for inspections and weather. Communicate with neighbors in advance; a friendly notice about work hours, parking, and dust control reduces friction and makes the project safer for everyone.

When choosing your team, look for:

– Relevant experience with your structure type and neighborhood conditions

– Proof of licensing, insurance, and references for recent projects of similar scale

– A written method statement and safety plan, including dust and noise mitigation

– A diversion strategy with target percentages for salvage and recycling

– Clear communication habits and a single point of contact for daily questions

Before mobilization, hold a kickoff meeting to review the sequence, confirm utility statuses, walk through site access routes, and mark any items to remain. Establish how change orders will be handled and who authorizes them. At project closeout, request a simple package: disposal tickets, diversion summary, before-and-after photos, and a letter certifying that utilities were properly capped or disconnected and that any abatement was completed according to regulations.

Summary for homeowners and small developers: define your goals, choose a method that fits your priorities, respect the permitting and safety sequence, and treat environmental performance as a cost-savvy advantage. Do these well, and your teardown becomes a confident step toward what comes next—whether that’s a new foundation, a garden, or a clean slate ready for your plans.