Learn about House Demolition

Why House Demolition Matters: Outline and Roadmap

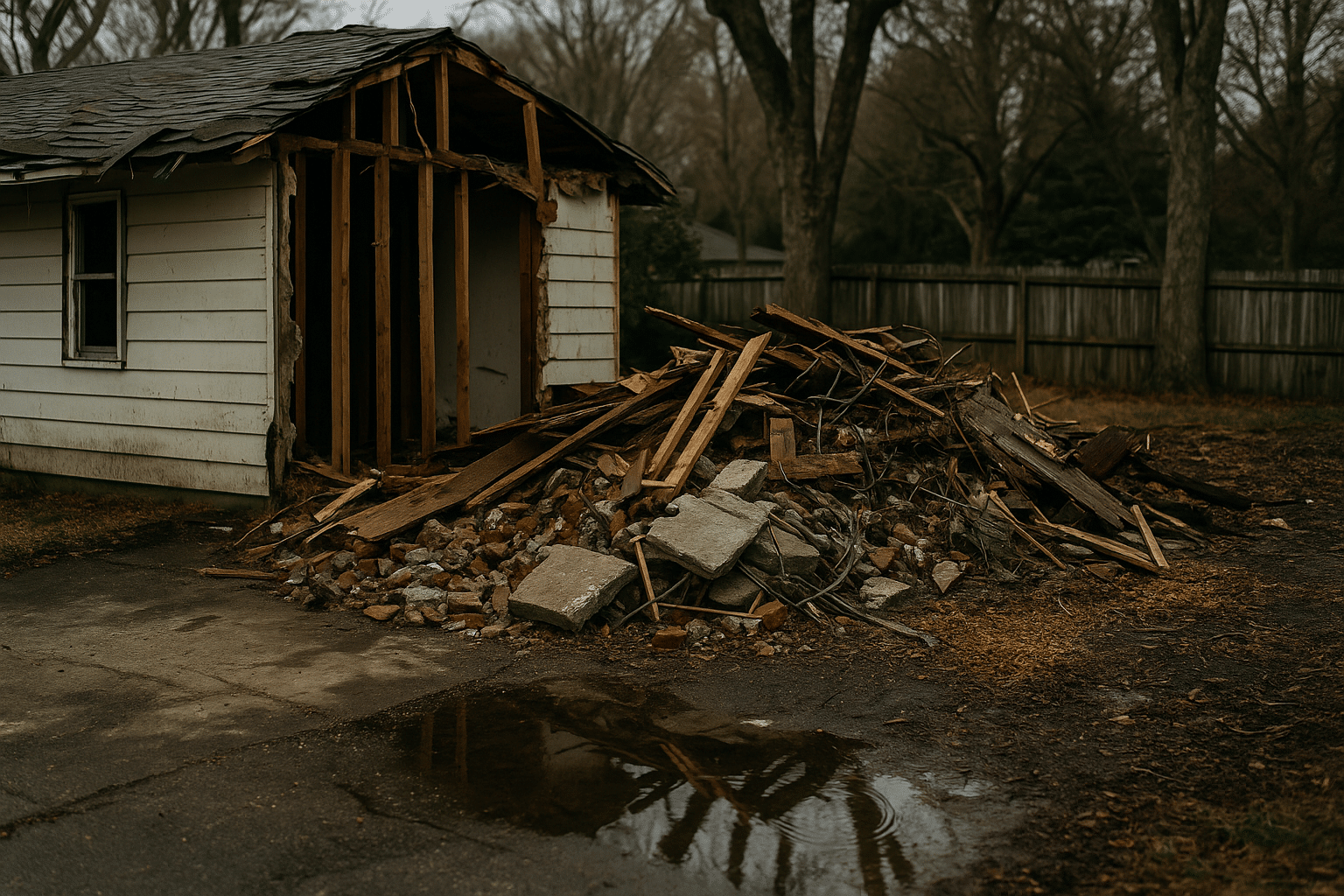

Demolishing a house isn’t simply about knocking down walls; it’s a strategic reset with implications for safety, cost, neighborhood character, and the environment. Homeowners consider demolition for many reasons: severe structural damage, outdated layouts that resist efficient renovation, remediation of hazardous materials, or to clear the way for a new build that meets modern energy codes. When handled methodically, demolition preserves value, reduces risk, and sets the stage for a smoother construction project that follows.

Before diving in, it helps to see the whole journey at a glance. Below is a concise map of the terrain we’ll cover, so you can spot how each piece connects to your goals:

– Planning and permits: surveys, utility disconnects, hazardous-material inspections, and neighborhood considerations.

– Methods: mechanical demolition, selective deconstruction, hybrid strategies, and why implosion is rarely used for houses.

– Safety and environment: dust control, noise management, recycling targets, and responsible handling of regulated materials.

– Budget and schedule: estimating costs, sequencing tasks, selecting a qualified contractor, and preparing for the next build.

– Conclusion and next steps: a clear, practical checklist tailored to owners preparing to act.

Think of demolition as a relay race: paperwork passes the baton to fieldwork, which hands off to cleanup and site preparation. Each handoff can speed or stall the project. For example, a permit delayed by an incomplete asbestos survey can idle equipment for days, elevating costs. On the other hand, a well-planned salvage strategy can offset expenses by reclaiming materials like timber, bricks, fixtures, and copper. In many communities, thoughtful waste diversion is more than a badge of honor; it’s increasingly a compliance requirement tied to permits or disposal fees.

Clarity now prevents surprises later. By the end of this guide, you’ll understand which method suits your site, what local rules often require, how to structure a realistic timeline, and where environmental gains can coincide with cost control. Demolition is the quiet hero of a successful build—done correctly, it leaves you with a clean, compacted, code-compliant slate and the confidence to move forward.

Planning, Permits, and Pre-Demolition Checks

Good demolition begins on paper. Most jurisdictions require permits, proof of utility shutoffs, and environmental surveys before any structure is taken down. A thorough pre-demolition plan typically includes a site survey, verification of property lines, review of easements, and checks for encroachments that might complicate equipment access. Municipalities often request an asbestos inspection for structures built before certain dates, and some require lead-paint awareness procedures if painted surfaces will be disturbed during hand removal or saw cutting.

Early coordination with utilities prevents dangerous surprises. Service providers generally must issue disconnect confirmations for electricity, gas, water, and telecom. In many places, sewer capping and backflow protection are verified by inspection. If a fuel oil tank is present, regulations may require decommissioning or removal under specific procedures. These steps take time, so begin well ahead of your target start date.

Neighbors appreciate notice, and some cities require it. Sound and dust windows—allowable hours for noisy work and expectations for dust mitigation—are commonly embedded in municipal codes. Your plan should also address tree protection, sidewalk permits for equipment staging, and traffic control if heavy trucks will use narrow streets. Erosion and sediment control (for example, silt fencing and stabilized construction entrances) helps keep sediment off roads and out of storm drains.

Helpful items to assemble before demolition starts include:

– A complete permit set: demolition permit, utility disconnect letters, and any required environmental reports.

– A salvage and recycling plan: which materials you intend to reclaim, reuse, or recycle, and where they will go.

– A site logistics plan: equipment routes, debris staging, fencing, and emergency contacts.

– Insurance and bonding: certificates naming you and, if applicable, your lender as insured parties.

Finally, take a thorough photographic record—exterior elevations, interior rooms, and site conditions. Photos support insurance questions, document preexisting cracks in pavements and neighboring walls, and streamline final inspections. With these boxes checked, you’ll reduce last-minute scrambles and create a predictable runway for fieldwork.

Choosing a Demolition Method: Mechanical, Deconstruction, Hybrid, and Implosion

There is no single approach to house demolition; the right method depends on structure type, access, environmental goals, and your schedule. Mechanical demolition uses heavy equipment—such as excavators fitted with buckets, thumbs, or shears—to collapse and sort the structure quickly. It’s the most common option for typical wood-framed houses, often completing primary teardown in one to three days, followed by debris sorting and hauling. Costs vary by region and disposal fees but are frequently estimated on a per-square-foot basis.

Selective deconstruction is the surgical counterpart. Crews remove materials by hand or with light tools to preserve reusable components: flooring, cabinetry, doors, fixtures, dimensional lumber, and sometimes brick. Deconstruction takes longer—often multiple weeks for an average-sized home—yet can achieve significantly higher waste diversion. Some projects report diverting 60–90% of materials from landfills by combining deconstruction with targeted recycling streams for metals, concrete, asphalt shingles, and clean wood.

Hybrid strategies blend the two, hand-stripping high-value items before bringing in equipment for the remaining structure. This approach can capture much of the salvage value and still hit a practical schedule. Implosion—using carefully sequenced charges to make a structure collapse inward—is rarely chosen for single-family homes due to permitting complexity, proximity to neighbors, and the availability of faster, lower-risk mechanical methods.

How do these methods compare in practice for a wood-frame house of, say, 1,800 square feet?

– Speed: Mechanical might finish major teardown in 1–3 days; hybrid could take 4–8 days; deconstruction often runs several weeks.

– Noise and dust: Mechanical is louder during active equipment use; deconstruction spreads noise over more days, but both should include dust suppression via water mist.

– Cost: Mechanical commonly has the lowest upfront labor cost; deconstruction adds labor hours but can recoup value through salvage and reduced disposal tonnage.

– Environmental outcomes: Deconstruction and hybrid methods enhance reuse and recycling, reducing embodied-carbon impacts of new materials.

Site constraints also shape the choice. Tight urban lots may require smaller equipment and more handwork to protect adjacent structures. Homes with heavy masonry or thick stucco may benefit from different attachments to break and sort materials efficiently. In wildfire or flood rebuilds where speed matters, mechanical demolition paired with a well-planned recycling program often strikes a workable balance. Ultimately, align the method with your priorities—timeline, budget, salvage goals, and local regulatory expectations.

Safety, Environmental Stewardship, and Responsible Disposal

Safety and environmental performance are inseparable on a demolition site. A competent crew plans for both, beginning with hazard identification and controls. Common risks include unstable structures, hidden utilities, nails and sharp metal, and airborne dust. Crews typically stage the site with fencing, signage, fire extinguishers, and clearly marked entry points, and they sequence work to avoid putting people or property in harm’s way. Equipment operators and spotters maintain constant communication to keep swing radiuses clear.

Environmental diligence starts with regulated materials. Asbestos-containing materials—often found in older flooring, mastic, pipe insulation, roofing, or cement board—must be identified by accredited inspectors and handled under jurisdiction-specific rules. Lead-based paint, commonly present in pre-regulation homes, triggers safe work practices to reduce dust and prevent contamination. Refrigerants in appliances are captured by certified technicians before disposal. Tanks, pesticides, or household chemicals are segregated and managed according to local requirements.

Thoughtful waste management lowers both tipping fees and environmental footprint. Typical streams include:

– Metals: steel, copper, aluminum often recycled with market credits.

– Concrete and masonry: crushed for base material on roads or building pads.

– Clean wood: chipped for mulch or biomass fuel, or reclaimed as lumber where feasible.

– Asphalt shingles: processed in some regions for pavement mixes.

– Gypsum: recycled in select markets or used in agricultural applications where allowed.

Dust control matters to workers and neighbors. Water misting at the point of impact, wind monitoring, and pausing during high gusts are practical measures. Noise can be reduced by limiting engine idle times and scheduling the loudest activities within permitted hours. Erosion control—straw wattles, silt fence, stabilized entrances—keeps sediment onsite during and after demolition, particularly if rains arrive before new construction begins.

The environmental benefits of deconstruction and robust recycling can be substantial. Reusing lumber or doors displaces new manufacturing, saving embodied energy. Recycling concrete into base material avoids quarrying and trucking impacts. Many projects that pursue a hybrid approach report diverting more than half of debris by weight, which is increasingly aligned with municipal mandates. Put simply, safer sites tend to be greener sites—because both depend on planning, documentation, and disciplined execution.

Budget, Timeline, Contractor Selection, and Conclusion

Cost clarity begins with scope. A typical residential demolition budget accounts for permitting, environmental surveys, utility shutoffs, equipment and labor, hauling and disposal, recycling fees or credits, site protection, and final grading. Because disposal rates and access conditions vary widely, reputable estimators conduct a site visit and review local dump fees before quoting. Many homeowners carry a contingency—often 10–15%—for surprises like hidden foundations, undocumented slabs, or extra trips to manage wet debris after storms.

Schedules compress when paperwork precedes fieldwork. A streamlined timeline might look like this:

– Preconstruction (2–6 weeks): surveys, permits, utility disconnects, asbestos and lead checks, salvage planning.

– Fieldwork (1–10+ days): depending on method—mechanical, hybrid, or deconstruction—with daily debris removal.

– Closeout (3–10 days): final sorting, site cleanup, grading, compaction testing, and permit sign-off.

Choosing a contractor is as important as choosing a method. Seek firms with relevant licenses, active insurance, and a record of clean inspections. Ask for recent references, photos of similar projects, and details on their recycling performance. Proposals should describe equipment to be used, dust and noise controls, daily housekeeping standards, emergency procedures, and how utilities will be verified as inactive. Contracts can reference disposal destinations, target diversion rates, and documentation you’ll receive at the end—such as weight tickets, recycling receipts, and a demolition certificate if your jurisdiction issues one.

As demolition wraps, attention shifts to what comes next. Contractors typically rough grade the site, remove temporary protections, and prepare the pad for future construction. Where required, a compaction test documents soil density to support new foundations. You may also retain erosion controls and temporary fencing until the new build begins. Keep a digital file with permits, inspection results, photos, and disposal documentation; it will save time during the next permit review.

Conclusion: Demolition sets the tone for everything that follows. With careful planning, a suitable method, and a disciplined contractor, you can control risk, protect neighbors, and push substantial waste out of the landfill stream. If you’re a homeowner weighing renovation versus replacement, use the insights here to form a checklist, gather comparable bids, and align the schedule with design and financing milestones. The more attention you invest now, the smoother your next build will be—beginning on a clean, safe, and well-prepared site.